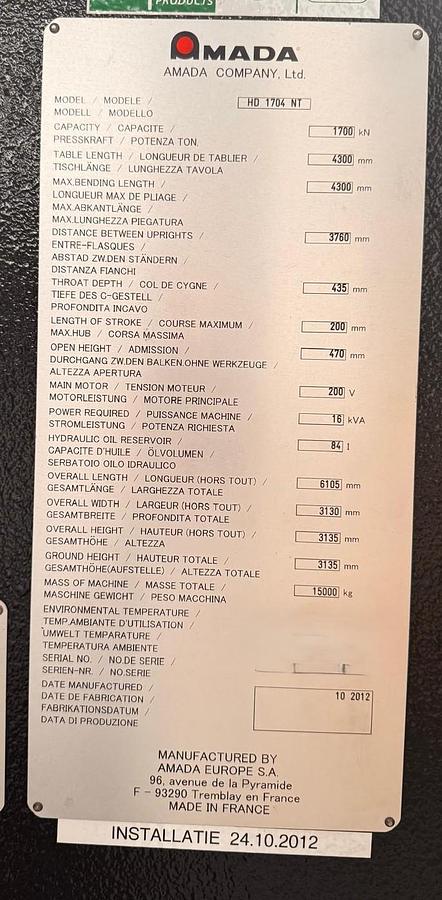

2012 AMADA HD 1704 NT

Specifications

| Manufacturer | AMADA |

| Model | HD 1704 NT |

| Year | 2012 |

| Condition | Used |

| Stock Number | 00033 |

| Pressing force | 1700 kN |

| Table length | 4300 mm |

| Max bending length | 4300 mm |

| Distance between uprights | 3760 mm |

| Throat depth | 435 mm |

| Length of stroke | 200 mm |

| Open height | 470 mm |

| Overall length | 6105 mm |

| Overal width | 3130 mm |

| Overall Height | 3135 mm |

| Machine weight | 15000 kg |

Description

Opportunity to buy a AMADA press brake with 4300 mm bending length, 170T bending force, 7 axis (Y1,Y2, X1, X2, R, Z1, Z2) and offline software « AP100+BendCam ».

Full technical details in the attached document.

Viewing under power possible upon appointment.

The machine's standard equipment includes:

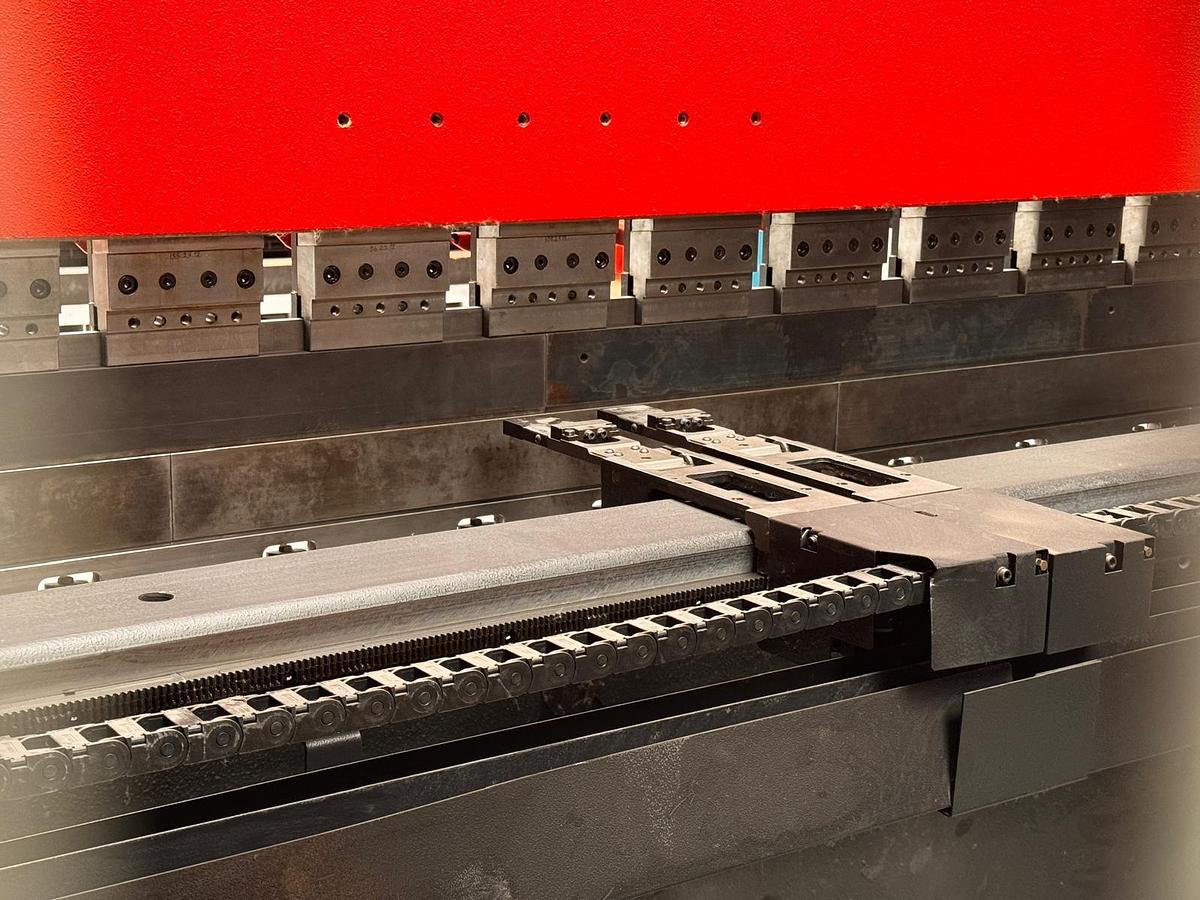

Stable machine frame with electric "Slit Crowning" mechanism in the lower table

Servo-hydraulic "Hybrid Drive" drive for the upper beam

Spherical suspension of the cylinders on the upper beam

5-axis controlled back gauge (X1X2, R, Z1Z2)

Touch screen control "AMNC-PC" under Windows XPe

Infrared digital angle gauge DIGIPRO-IR

Infrared receiver for transmission from DIGIPRO to the control

OPTICON barcode reader for AP100 offline software

21 fractional "S GRIP" type stamp holders equipped with front quick clamps

Measuring rod on the upper beam

Network card

External memory: USB connection with included USB key

Electric double-acting foot pedal with safety contact Locking pedal

Hydraulic tank filled with 84 liters of oil

Safety doors on the rear and sides of the press brake

Electrical cabinet climate-controlled

Set of hand tools: flat wrenches, Allen wrenches, and key for adjusting the back gauge fingers.

Technical manual (installation, use, and maintenance)

Offline programming software "AP100 + BendCam"

Please note: The information on this page has been obtained to the best of our ability and belief. This information is provided in good faith, but its accuracy is not guaranteed. Accordingly, this information is not binding and does not constitute a contractual condition. We recommend that you check all essential details during an inspection of the machine. To save unnecessary travel costs for our customers, in most cases we recommend organizing a live video inspection.